These are the most common CFD usage requirements from clients:

CFD can be applied to a wide range of products: every object working in a fluid environment (e.g. air, water, etc.) could be potentially affected by fluid-dynamic forces. A correct estimation of these contributes to the product validation and enhancement.

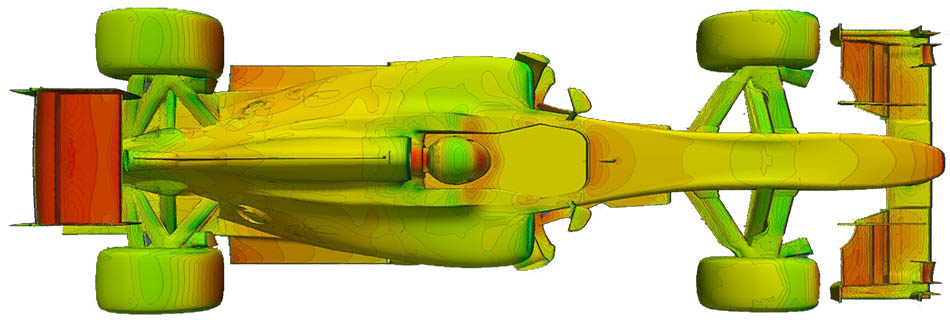

Compared to other fluid dynamics analysis tools, the extensive characterisation of the flow is a unique property of CFD simulation. Since flow properties are available across the entire fluid flow sector, understanding the behaviour of aerodynamic devices is quicker and easier.

Given the definition of a product's geometry, its performance can be mapped over a wide range of working conditions. These can also be automated in the CFD process, providing a quick and accurate tool for performance estimation.