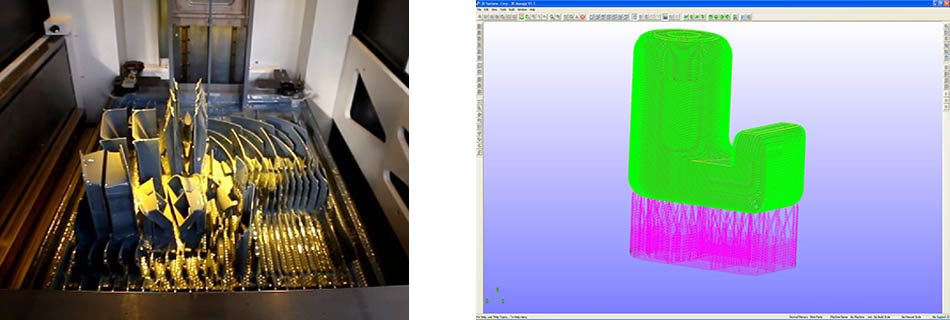

Rapid prototyping uses three-dimensional CAD files and dedicated printers to create pieces with complex geometric forms.

This process allows prototype components to be quickly manufactured using special plastic or ceramic materials. Firstly, we calculate the geometric specifications before the part is drawn in 3D using CAD software and engineering data. Finally, the printing machine reads the CAD file and creates multiple overlapping layers in order to complete the shape. This process is frequently used to try different aerodynamic configurations on models during wind tunnel testing.