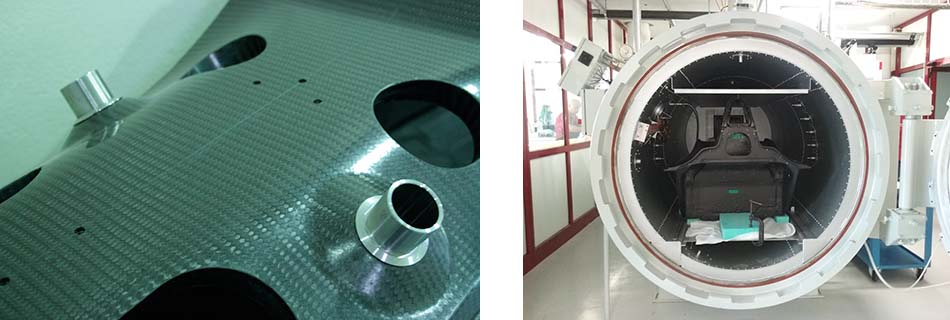

Since 1994 FONDTECH produces in house all metallic and carbon components of the scale models tested in its wind tunnels.

Decades of experience combined with CNC machining, rapid prototyping, autoclave and oven systems facilities allow FONDTECH to also manufacture composite parts for full scale, vehicles. FONDTECH combines high technology production and advanced engineering expertise, offering support in the whole process from concept to analysis, through CAD design, FEM and CFD, and from manufacturing to structural testing, through CAM system production, patterns machining, hand plies layup, components and fixings bonding, drilling, assembly, dimensional check and laboratory quality analysis. Beside the traditional racecar applications, FONDTECH high technology process is ideal for any high level of composite design in various fields (land and see vehicles, drones, small wind turbines, carbon furnitures).