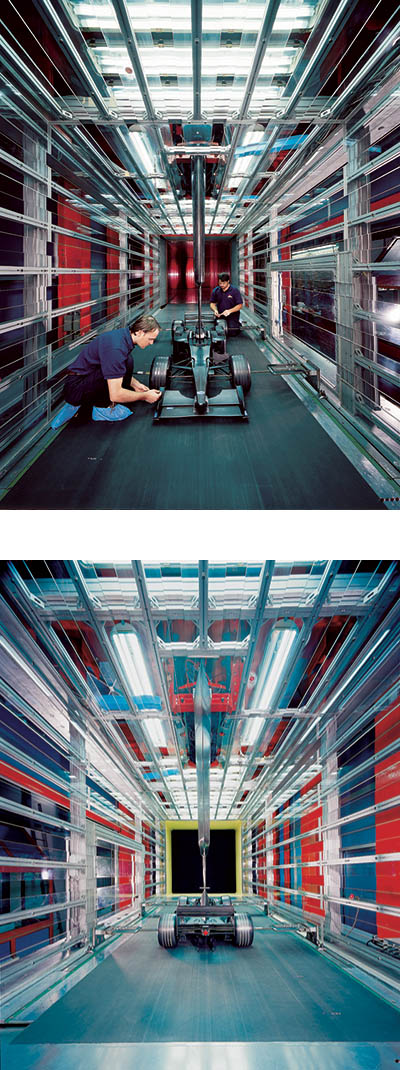

The FondTech 2 and Aerolab wind tunnels are the largest and most recent tunnels at FondTech's disposal, and feature state-of-the-art systems and devices for high performance automotive wind tunnel testing.

Our first tunnel – FondTech 1 – was built in the early 1990s and paved the way for many successful racing car developments. It is now used for lower-budget programmes and non-automotive applications.

FondTech 1 - Tecnical Details

General specifications

- Single return closed circuit

- 48m long x 16m wide x 7m high

- 100m rectangular perimeter air path along centreline

- Walls in aluminium extruded panels with steel frames

- Nozzle contraction ratio 9:1

- Flow cooling system (water radiator)

- Speed nominal range from 30m/s to 50m/s

Fan

- Single axial fan

- 3.6m diameter

- Fan DC motor, power 375kW

- Variable rpm speed control systems

Test section

- Area 5m2

- Dimensions: 2.23m x 2.23m x 7m

- Closed or variable slotted wall on demand

- Suitable for 40% - 50% automotive models

Moving ground

- Dimensions: 2m wide x 4.1m long

- Active tensioning and tracking controls

- Water cooled belt plate

- Belt suction system

- Upstream boundary layer suction

- Boundary layer displacement thickness at model nose: 0.3mm

Model support and wheel struts

- 2 degrees of freedom (heave and pitch) twin struts model support

- Yaw and roll capabilities

- Model motion control with LVDTs and Laser systems

- Unsteady testing capability

- Manually adjustable wheel supports

Model forces and pressure measurement

- 6-components internal balances

- 1-component wheel balances

- Additional balances for model wings available

- Pressure scanners for cooling and pressure distribution acquisition

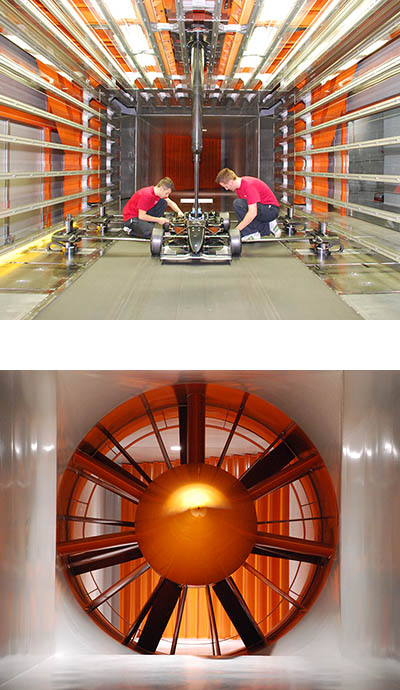

FondTech 2 - Technical Details

General specifications

- Single return closed circuit

- 46m long x 15m wide x 7m high

- 100m rectangular perimeter air path along centreline

- Steel walls with steel frames

- Nozzle contraction ratio 6:1

- Flow cooling system (water radiator)

- Speed nominal range from 30m/s to 50m/s

Fan

- Single axial fan

- 4.1m diameter

- Fan DC motor, power 610kW

- Variable rpm speed control systems

Test section

- Area 7.5m2

- Dimensions: 2.23m x 3.35m x 8m

- 27% slotted wall

- Suitable for 50% - 60% automotive models

Moving ground

- Dimensions: 2m wide x 5.4m long

- Active tensioning and tracking controls

- Water cooled belt plate

- Belt suction system

- Upstream boundary layer suction

- Boundary layer displacement thickness at model nose: 0.3mm

Model support and wheel struts

- 4 degrees of freedom (heave, pitch, roll and yaw) twin struts model support

- Model motion control with LVDTs and Laser systems

- Unsteady testing capability

- Remotely controlled wheel supports

Model forces and pressure measurement

- 6-components internal balances

- 3-components wheel hub balances (Wheel-On model)

- 1-components wheel balances (Wheel-Off model)

- Additional 3-components balances for model wings available

- Pressure scanners for cooling and pressure distribution acquisition

Aerolab - Technical Details

General specifications

- Single return closed circuit

- 46m long x 15m wide x 7m high

- 100m rectangular perimeter air path along centreline

- Steel walls with steel frames

- Nozzle contraction ratio 6:1

- Flow cooling system (water radiator)

- Speed nominal range from 30m/s to 50m/s

- Single axial fan

- 4.1m diameter

- Fan DC motor, power 610kW

- Variable rpm speed control systems

Test section

- Area 7.5m2

- Dimensions: 2.23m x 3.35m x 8m

- 27% slotted wall

- Suitable for 50% - 60% automotive models

Moving ground

- Dimensions: 2m wide x 5.4m long

- Active tensioning and tracking controls

- Water cooled belt plate

- Belt suction system

- Upstream boundary layer suction

- Boundary layer displacement thickness at model nose: 0.3mm

Model support and wheel struts

- 4 degrees of freedom (heave, pitch, roll and yaw) twin struts model support

- Model motion control with LVDTs and Laser systems

- Unsteady testing capability

- Remotely controlled wheel supports

Model forces and pressure measurement

- 6-components internal balances

- 3-components wheel hub balances (Wheel-On model)

- 1-components wheel balances (Wheel-Off model)

- Additional 3-components balances for model wings available

- Pressure scanners for cooling and pressure distribution acquisition